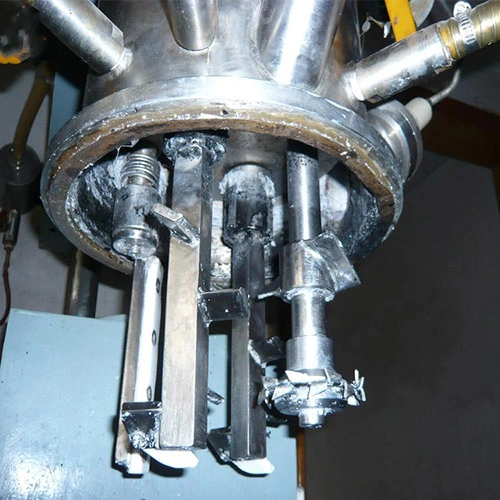

Silicone Sealants Glass Glue Sealant Planetary Mixer Mixing and Dispersing Equipment

Overview Detailed Photos Product Description 1)Base material dispersing mixer/Vacuum kneader,2)High viscosity pump 3)Bas

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | NHZ |

| Certification | CE, ISO |

| Application Area | Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Milling |

| Operating type | Cycle Operating |

| Condition | New |

| Power | Customizable |

| Heating Way | Oil Electric |

| Material | SS304 |

| Warranty Period | 1year |

| Transport Package | Customizable |

| Specification | 6L TO 2000L |

| Trademark | JCT |

| Origin | Foshan |

| HS Code | 8474390000 |

| Production Capacity | 5000picecs/Year |

Product Description

Product Description

1)Base material dispersing mixer/Vacuum kneader,2)High viscosity pump 3)Base storage tank,4)heating system(according to actual requirements)5)Vacuum system,6)Three roller grinding machine(according to actual requirements)7)multifunctional-dispersing machine8)Hydraulic discharging machine,9)Cooling system,10)Sealant filling machine( plastic bottle filling machine,film filling machine)11)Raw material storage tank12)Oven,13)Batching system,

| model | feeding voluma | planetary motor | high-speed motor | Revolution speed | Rotation speed | High speed dispersion speed | Remarks |

| DLH-6L | 3.6 | 1.5 | 1.5 | 27 | 43 | 0~1000 | |

| DLH-20L | 12 | 3 | 3 | 27 | 43 | 0~1000 | |

| DLH-60L | 36 | 4 | 4 | 27 | 43 | 0~1000 | |

| DLH-100L | 60 | 7.5 | 5.5 | 27 | 43 | 0~1000 | |

| DLH-200L | 120 | 15 | 11 | 27 | 43 | 0~1000 | |

| DLH-350L | 210 | 18.5 | 18.5 | 27 | 43 | 0~1000 | |

| DLH-600L | 360 | 22 | 22 | 27 | 43 | 0~1000 | |

| DLH-1000L | 600 | 37 | 30 | 23 | 43 | 0~1000 | |

| DLH-1500L | 900 | 45 | 45 | 23 | 43 | 0~1000 | |

| DLH-2000L | 1200 | 55 | 45 | 23 | 43 | 0~1000 |

1)Pulp partThe solvent through the liquid metering device is added to the liquid material groove , by Vacuum suction to emulsifying kettle , start low speed anchor mixer , the powder material is sucked into the vacuum emulsifying tank for continuous stirred 10 minutes , then turn on the two sets of vertical high shear emulsifying 10 minutes , finally use horizontal emulsion machine , continuous cycle 30 minutes , finished slurry . A high shear inside the tank and an emulsion pump outside the tank are also used ,Ensure further refinement of materials , and greatly shorten the operation time 2)Paint part By vacuum , resin , film-forming agent from the liquid tank into the low-speed stirred tank the bag filter is sucked into the low-speed mixer , the emulsion or solvent ,additives , slurry mixing , then adding additives ( thickener ) , blending paint .3 ) Filter packing After a good tune paint , vacuum defoaming after 5 minutes , stirring was stopped by a bag coating to semi-automatic filling machine for packaging , When the coating material using a two bag filters , can be switched with each use , does not affect the filling speed