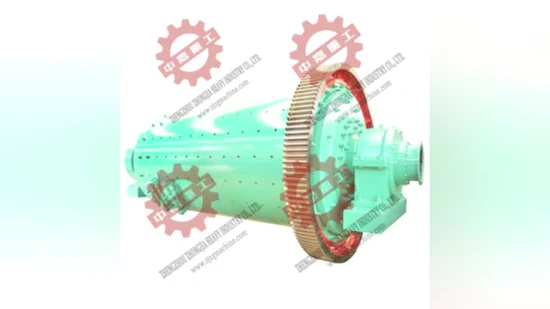

Gold Grinding Plant Industrial Wet Gold Mining Ball Mill Equipment

The appearance of the ball mill is a horizontal cylindrical shape, which has the characteristics of high operation effic

Send your inquiryDESCRIPTION

Basic Info

| Rotationl Speed | 20-22r/min |

| Application | Mine |

| Materials | Ore,Copper,Gold,Aluminum |

| Condition | New |

| Warranty | 1year |

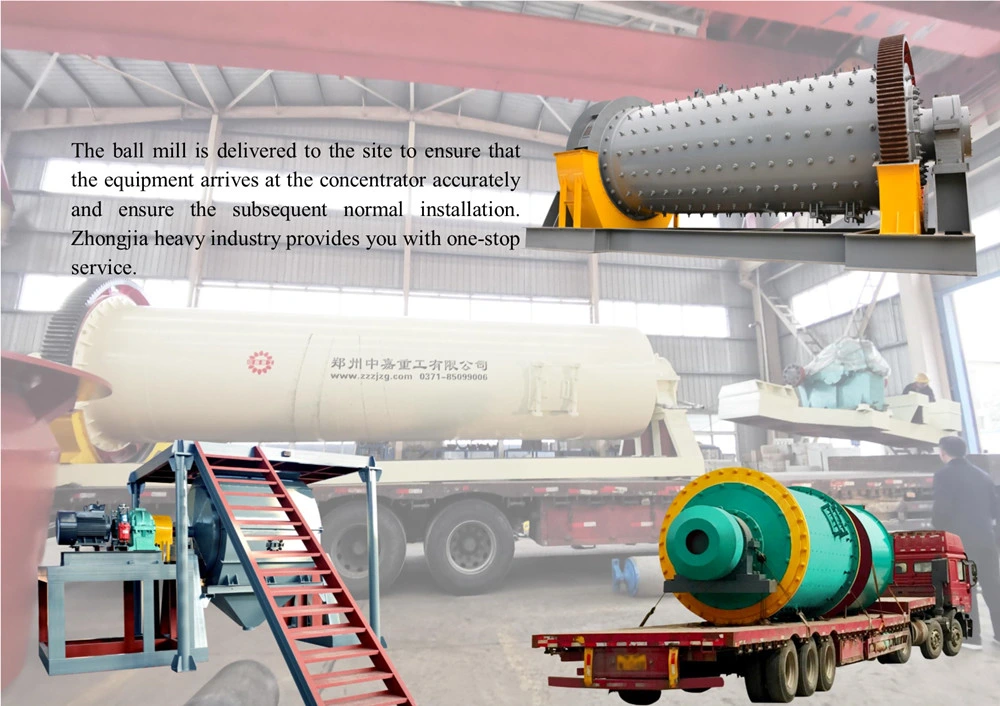

| After-sales Service | Installation Guide, Spare Part Supplying |

| Factory Visit | Welcome |

| Spare Parts | Supply |

| Discharging Size | 0.074 to 0.89 mm |

| Color | Customizable |

| Operation Training | Provide |

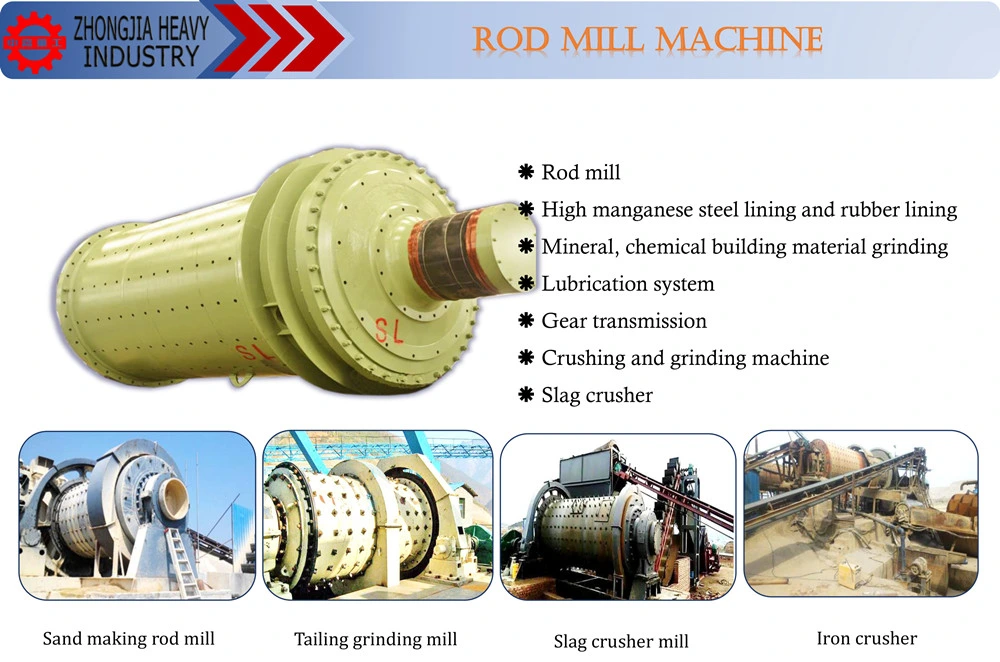

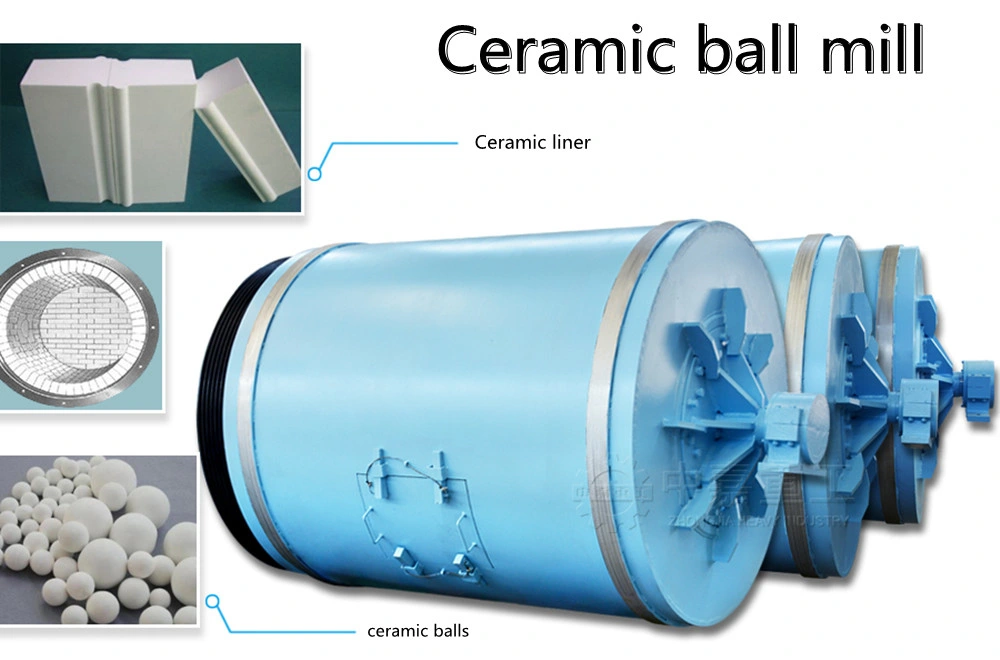

| Grinding Media | Steel Balls,Ceramic Balls,Steel Bar |

| Lining | Steel Lining, Rubber Lining, Ceramic Lining |

| Quality | High Level |

| Max Feeding Size | 25mm |

| Transport Package | Container |

| Trademark | ZJZG |

| Origin | Zhengzhou |

| Production Capacity | 1-140t/H |

Product Description

Working principle of rod mill: The liner of the rod mill is mostly corrugated, stepped or wedge-shaped. According to different discharge methods, it can be divided into central discharge type (overflow type) and peripheral discharge type (open type). The diameter of the hollow journal at the discharge end is much larger than that of the overflow ball mill of the same specification, which is to reduce the pulp level and accelerate the speed of the pulp through the rod mill. Rod mills rely on rod pressure and grinding force to grind ore. When the rod hits the ore, the coarse particles are first broken up, and then the smaller particles are ground: the rod is in line contact with the rod, and the ball is in point contact, so as the rod rotates along the barrel wall When rising, the coarse particles are sandwiched between them, which is similar to the role of a bar screen, allowing the fine particles to pass through the gaps between the bars, which is also conducive to crushing the coarse particles and making the coarse particles concentrated in the place where the grinding medium hits. Therefore, the rod mill has a selective grinding effect, the product particle size is more uniform, and the over-grinding is less.

Inquiry Service

More details we needed for sending you more suitable quotation,1. What kind of raw material do you want to process?2. What is the capacity per hour do you need?3. What is the raw material input size?4. What is the finished size you required?Any inquiries of our ball mill will be highly regarded and we will give you the best quotation ASAP. Your satisfaction is our final and forever pursuit.

Related Products