Gold Wet Grinding Machine Wet Pan Mill Three Roll Mill

Overview Product Description Gold Grinding Machine (wet pan mill) , which is named by the diameter of grinding roller. I

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | PM Series |

| Type | Wet Pan Mill |

| Motor Type | AC Motor |

| Motor Power | 5.5-25kw |

| Rotationl Speed | 20-22r/min |

| Application | Mine: Gold, Silver, Lead, Zinc, Molybdenum, Ferrum |

| Materials | High Wearable Steel |

| Condition | New |

| Warranty | 2 Years |

| After-sales Service | Engineer Guidance/Video Guidance |

| Usage | Concentration of Gold, Silver, Lead, Zinc, Molybde |

| Spare Parts | Grinding Roller,Grinding Base,Belt,etc. |

| Feeding Size | 0-30mm |

| Transport Package | Export Packing Standard |

| Specification | Differ from different models |

| Trademark | Gelin |

| Origin | China |

| Production Capacity | 150sets/Month |

Product Description

Product Description

Gold Grinding Machine (wet pan mill), which is named by the diameter of grinding roller. It is mainly used for concentration of gold, silver, lead, zinc, molybdenum, ferrum, copper, antimony, tungsten and tin etc.. In Sudan, at least 85% gold miners are using the machine in their gold processing system. The most important point is that our customers can get pure gold directly after wet pan mill, which is suitable for miners who want to begin from small business.

Features

1. Less investment.2. Easy to operation and maintenance. 3. High efficiency and saving power.4. It can take the place of ball mill because all the materials that ball mill can handle, the wet mill machine can handle as well. 5. The Best price river gold widely used Sudan China wet pan mill for gold is the ideal equipment for small and medium enterprises that are in the field of ore dressing.6. The wet mill machine made by Z-land, can offer the seal cover to reduce the air pollution.

Product Parameters

| Model | Input size(mm) | Rotation Speed (r/min) | Motor Power(kw) | Dimension (mm) | Weight(t) |

| PM-1000 | 30 | 13-15 | 5.5 | 1000×200×80×250±20 | 4.5 |

| PM-1100A | 17-19 | 7.5 | 1100×200×80×250±20 | 5 | |

| PM-1100B | 23-25 | 7.5 | 1100×200×80×250±20 | 5 | |

| PM-1200A | 17-19 | 7.5 | 1200×200×80×250±20 | 5.5 | |

| PM-1200B | 23-25 | 7.5 | 1200×200×80×250±20 | 5.5 | |

| PM-1300A | 16-18 | 15 | 1300×250×150×350±20 | 7.5 | |

| PM-1300B | 21-23 | 15 | 1300×250×150×350±20 | 7.5 | |

| PM-1350A | 16-18 | 18.5 | 1350×250×150×350±20 | 8 | |

| PM-1350B | 21-23 | 18.5 | 1350×250×150×350±20 | 8 | |

| PM-1400A | 16-18 | 18.5 | 1400×250×150×350±20 | 8.5 | |

| PM-1400B | 21-23 | 18.5 | 1400×250×150×350±20 | 8.5 | |

| PM-1500A | 20-22 | 22 | 1500×350×200×460±20 | 13.5 | |

| PM-1500B | 20-22 | 22 | 1500×350×150×460±20 | 12.3 | |

| PM-1500C | 20-22 | 22 | 1500×300×150×420±20 | 11.3 | |

| PM-1600A | 20-22 | 25 | 1600×400×200×500±20 | 14.5 | |

| Note:Dimension part means roller diameter*roller thickness*grinding basin thickness * grinding basin width | |||||

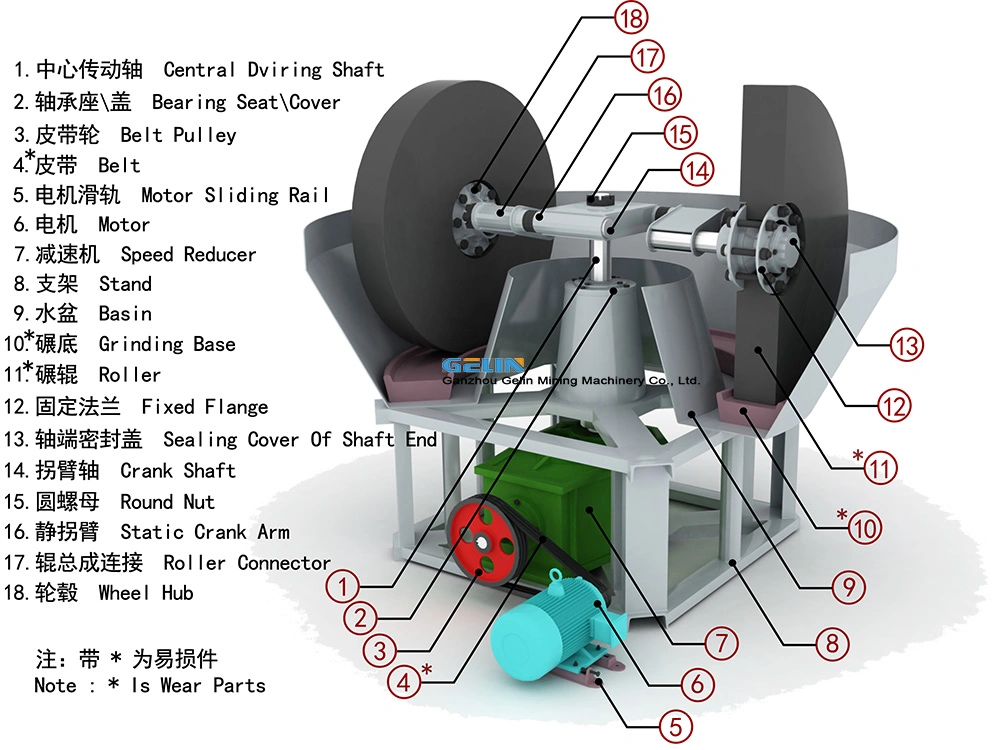

Structure and Working Principle

Wet pan mill is mainly consists of driving device, frame, water basin, grinding rollers and grinding base, etc.

Working Principle:First, the motor transfers power to the decelerator, then the central drive shaft transfers to the horizontal shaft, finally the Roller moves the anticlockwise direction, the material in the wet mill is ground into fine particles.

Detailed Photos

Application

Packaging & Shipping

Company Profile

Ganzhou Gelin Mining Machinery is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, magnetic/gravity separation etc. in China.the machines are excellent for processing gold,diamond,iron ore, ilmenite, manganese ore etc. Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin's equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc. Sincerely welcome to visit our factory.

Customer VisitingOur ServicesOne Stop solution for beneficiation plant service: 1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc. 2.Arrange mineral beneficiation experiment after received the material sample and beneficiation test report will be done after test.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings. 4.Manufacturing the necessary equipments and arrange the shipment. 5.Complete services for Installation and commissioning and technical training(operating training,common problem solving training). After-sale Service Regularly visit customers to provide after- sale technical supports and to solve problems of beneficiation plant. For equipments supplied,we could provide one-year warranty and provide spare parts with preferential price in the long term and be responsible for any problems with the them.

FAQ

Q: Are you a trading company or a factory?A: We are a factory at Shicheng county with 110 workers,6 workshops covered 17,000m2 and office covered 2,500m2. Welcome to visit our factory at anytime. Q: What is your payment terms?

A: By TT(Telegraphic Transfer), 100% or 40% Deposit before production and 60% balance payment paid off before loading from factory.

Q: How long is the guarantee period of your products?

A: The guarantee period is 1-2 years, pls ask staff for more details. And we will supply lifelong technical support service and the spare parts at lowest cost.

Q: Is it possible to produce customized products ?

A: Yes, most of our products are produced as required.

Q: Is it possible to provide sample for your factory to do ore-dressing experiment?

A: Yes, engineering consulting is available and we'd like to arrange mineral beneficiation experiment after received your sample and provide the test report.

Related Products