High Viscosity Fluid Heating Mixing Tank with Scraping Mixer

Overview Product Parameters Main Technical Parameter: Detailed Photos Product Description General Description:This serio

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Powder Mixer |

| Mixer Type | Powder Mixer |

| Working | High Speed Mixer |

| Stirring Type | Spiral |

| Application | Powder |

| Certification | ISO |

| Application Area | Chemical |

| Layout Type | Verticle |

| Additional Capabilities | Milling, Granulating |

| Operating type | Cycle Operating |

| Condition | New |

| Keyword | Container Mixer |

| Model | Fhj-150 |

| Volume | 150L |

| Mixer Power | 4-5.5 Kw |

| Tilting Power | 0.37-0.55 Kw |

| Dimension | 1200*1420*2000 mm |

| PLC Controlled | Yes |

| Color Changing | Easy |

| Leakage or Solidified Particle | No |

| Operation | Safe |

| Transport Package | Plastic Film |

| Specification | 1200*1420*2000mm |

| Trademark | Lingyu |

| Origin | China |

| Production Capacity | 30PCS / Months |

Product Description

Main Technical Parameter:

| Model | Volume (L) | Mixing Powder (kW) | Crushing Power (kW) | tilting Power (kW) | Dimension (MM) |

| FHJ-150 | 150 | 5.5 | 0.55 | 1200*1420*2000 | |

| FHJ-300 | 300 | 11 | 4 | 1.1 | 2400*1700*2600 |

| FHJ-600 | 600 | 18.5 | 5.5 | 1.1 | 2700*1800*2950 |

| FHJ-1000 | 1000 | 30 | 7.5 | 1.5 | 2900*2000*3300 |

| FHJ-1500 | 1500 | 37 | 7.5 | 2.2 | 3300*2200*3400 |

| FHJ-2000 | 2000 | 55 | 7.5 | 3.0 | 3500*2400*3600 |

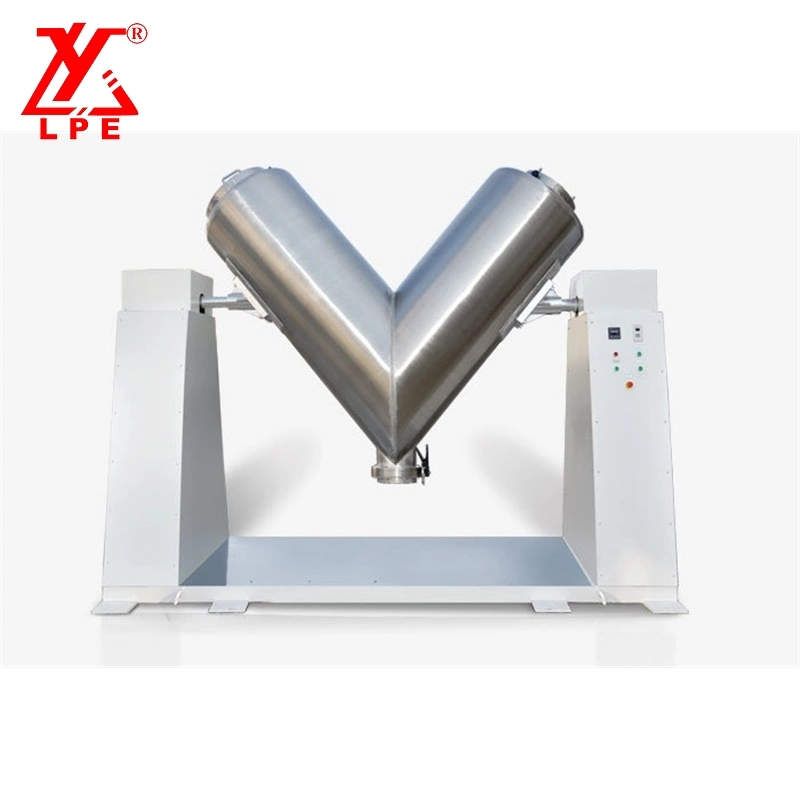

General Description:This serious of container mixer adopts movable container design ,can be applied for the mixing of various kinds of poweder and granular materials . The whole process adopts PLC controlling system ,with homogeneously mixing effect, high production effeciency and no solidified particles .

Working process:

After the cointainer filled with raw materials being pushed to the working positon ,it will be pneumatically lifted securely connected with the stirring head by the automatic controlling system . The stirring head will tilt together with the container meanwhile , then the mixing blade brings the material into rotary and centrifugal movement with geometrical circle , which ensures optimal mixing result. The container then returnes to the starting position after mixing process completed.

Features:

1. Processed controlled by PLC ,high automation

2. Mixing during cointainer tilting

3. Homogeneneous mixing High production efficiency

4. No leakage and solidified particle

5 .Pneumatic positioning ,clutching and lifting

6. Easy to clean and maintain

7 Safe to operate

8 Several containers for ciecular operation ,easy color changing

ApplicationsUsing Range

Widely used in chemical industry, medicine, compound fertilizer, dyes, pigments, rubber, building materials, food, milk powder,health products, feed, additives,aquaculture, biological engineering, fine chemical industry, ceramics, refractory materials,rare earth, plastic glass, new materials, nuclear materials and other industries.Ho

Company Profile

Lingyu Powder Machinery , established in 1999, is specialized in researching and manufacturing of powder coating processing equipment, with strong technical strength and abundant practical experience. Now we have hundreds of different machine models and get certifficates of CE approved by TUV Cermany, ATEX by Sira England and PSR11 by ECM Italy.Following the principle of "Quality first, Credit first and customer first", we are able to provide commissioning and installation support, formulation guidance and 24-hour aftersale service, which help us win great trust and support from customers.Now Lingyu has become a well-know manufacturer for powder coating processing equipment both at home and abroad, with No. 1 market share. Products have been successfully exported to 50 countries and regions. Friendly business relationship with many world famous powder coating manufaturers has been established and kept in long-term.We sincerely welcome you to our company for business visit and technical communication. Together with our sister company-Longcai Advanced Materials, mainly specialized in powder coating resins, we'll try our best to provide the best solution of powder coatings to our customers.

Packaging & Shipping

FAQ1. How is the quality of your products? Our products are prohibited according to national and international standard, and we take a test on every machine before delivery.2. Guarantee If the quality is not consistent with the description as we said or promised before you place order, we promise you refund.3.How about price? We have our own factory and can give you the lowest price,besides, we have a policy that "for saving time and absolutelyhonest business attitude, we quote as low as possible, discount can be given according to quantity.4. Can I customize? Most of our machine can be customized, so you can tell your kinds of requirement before ordering. We will try to meet yours requirement.

Related Products

-

![Market Satisfactory Rod Mill for Proppant Ceramic Sand Production Line]()

Market Satisfactory Rod Mill for Proppant Ceramic Sand Production Line

-

![Automatic Vertical 5-50ml Stick Bag Coffee Powder Granule Packing Machine]()

Automatic Vertical 5-50ml Stick Bag Coffee Powder Granule Packing Machine

-

![Multi-Function Automatic Fish Feed Powder Liquid Granule Horizontal Packing Machine]()

Multi-Function Automatic Fish Feed Powder Liquid Granule Horizontal Packing Machine

-

![Manufacture High Quality Chemical Industrial Heavy Top Entry Mixers Agitator]()

Manufacture High Quality Chemical Industrial Heavy Top Entry Mixers Agitator