Horizontal Double Shaft Paddle Mixing Machine Paddle Mixer for Powders and Granules Fertilizer/ Milk Powder/Protein/Vitamin Powder/ PVC/PE/ EVA

Horizontal Double Shaft Paddle Mixing Machine Paddle Mixer for Powders and Granules WORKING PRINCIPLE: Double shaft padd

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | WZL |

| After-sales Service | Yes |

| Warranty | 12 Months |

| Mixer Type | Powder Mixer |

| Working | Diffusion Mixer |

| Stirring Type | Forced |

| Certification | CE, ISO |

| Application Area | Chemical |

| Layout Type | Horizontal |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Drying, Coating |

| Operating type | Cycle Operating |

| Condition | New |

| Size | Manufacturing by Client′s Requirement |

| Type | Mixer |

| Transport Package | wooden case or by requirement |

| Specification | CE, ISO 9001 |

| Trademark | SL |

| Origin | China |

| Production Capacity | Tba |

Product Description

Horizontal Double Shaft Paddle Mixing Machine Paddle Mixer for Powders and GranulesWORKING PRINCIPLE:

Double shaft paddle mixer is a batch mixer with two counter-rotating shaft that are equipped with ten paddlesthey overlap each other following the driven unit, Blades generate centrifugal force during high speed rotation, spilling the material to the upper part in the barrel then material falling down( the vertex of material is in a so called instant non-gravity state). Driven by the blades material is mixed back and forth: also sheared and separated by the meshing space between the twin shafts ast and evenly mixed in the end

When mixing:

1. The horizontal axes make the material move up and down.

2. Rotation at opposition direction of the double axes makes materials exchange from left to right.

3. Paddle stirrers push material at angle 45 to move circularly in the cylinder, and the materials can reach good mixing effect under the movement of radial and axial orientation

1.Flexible material selectionMaterial can be carbon steel, manganese steel, ss304, 316L and 321;besides, different material can also be used in combination between the part contact with the raw material and the parts don't contact with the raw material.

2.Reliable driven unit

The four different driven combination launched by Shengli Co. can meet different requirements of two synchronous gear box, double output gear boxdouble synchronous planetary gear box, and the combination of reducer and chain.The combination of Sk-series double synchronous gear box is the best configuration for double shaft paddle mixer.

3.High efficiency mixing unit

According to the properties of raw materials, the paddle can be adjusted and designed accordinglyfor example adding wear-proof plate, Teflon plate, and saw-toothed paddle.Double shaft paddle mixer can be also added high speed breaking bar inside the barrel, scattering material following its flow.

4.Excellent discharging unit

Standard valve for double shaft paddle mixer is twin pneumatic planar flap valves.When close the valve, the planar flaps match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect5.Powerful auxiliary components Mixer is frequently equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacketsampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on.Different heat medium requires different jacket, it can be used for heating and cooling, while, the temperature should be within 250 Celsius degree.

6.Data sheet

| specification | WZL-0.3 | WZL-0.5 | WZL-1 | WZL-2 | WZL-3 | WZL-4 | WZL-6 | WZL-10 | WZL-15 | WZL-20 |

| working capacity(m³) | 0.18 | 0.3 | 0.6 | 1.2 | 1.8 | 2.4 | 3.6 | 6 | 9 | 12 |

| working capacity(kg) | 200 | 300 | 600 | 1200 | 1800 | 2500 | 3600 | 6000 | 9000 | 12000 |

| speed(RPM) | 60 | 60 | 53 | 43 | 43 | 35 | 35 | 29 | 22 | 18 |

| power(KW) | 5.5 | 7.5 | 11 | 22 | 30 | 37 | 44 | 60 | 90 | 150 |

| weight | 650 | 900 | 1300 | 2300 | 2800 | 3400 | 5000 | 6000 | 8500 | 12000 |

| length | 1600 | 1800 | 2400 | 2800 | 3200 | 3400 | 3700 | 4000 | 4600 | 5200 |

| width | 850 | 1000 | 1400 | 1700 | 1950 | 2000 | 2200 | 2600 | 3100 | 3500 |

| height | 950 | 1100 | 1800 | 1950 | 2000 | 2000 | 2300 | 2600 | 2800 | 3000 |

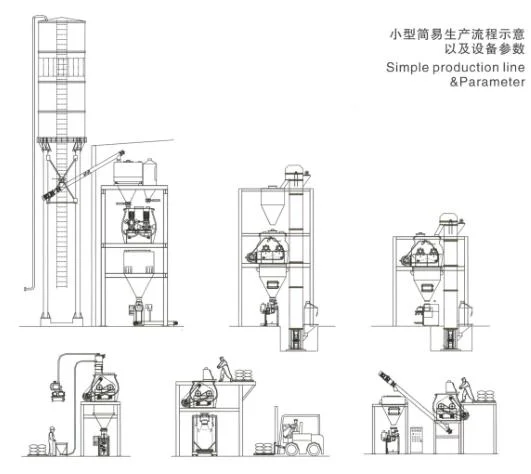

7.The production blending line like:

Feeding machine: manual feeding, crane big bag feeding, screw conveyor feeding, vacuum feeding, bucket elevator etc.

Mixing machine: doubel ribbon blender, single shaft mixer, mixing machine etc.

Filling machine: storage silo, screw conveyor, packing machine, big bag etc.

Simple system as dry ingredient bulk production mixing line like:

8. About us

Shanghai Shengli specializes in mixing equipment research, design, manufacture, sales and service. In past 26 years, we go deeply mixing processing filed and related technology, devote to research different kinds of mixer, modify and perfect existing mixing system, and develop new-type mixer equipment

Under working experience, we developed mixer processing machinery independently. With modern processing method, strict product management, high quality ,and professional service team, Shengli is becoming the preferred brand. We will keep researching new technology, solving mixing problems, providing more suitable mixer, promoting upgrades, and creating maximum value for customers.

Related Products

-

![1-5tph Dry Type Ceramic Sand Ball Mill Machine Equipment for Grinding Ceramic]()

1-5tph Dry Type Ceramic Sand Ball Mill Machine Equipment for Grinding Ceramic

-

![3-Roll Mill China Colloid Mill Bauxite Grinding Mill Supplier]()

3-Roll Mill China Colloid Mill Bauxite Grinding Mill Supplier

-

![Automatic 4/6/8 Heads Piston Pump Filling Machine for Food/Cosmetic/Beverage /Oil/Cream / Soap Liquid Paste Product Packing Machinery Machine Bottling Line]()

Automatic 4/6/8 Heads Piston Pump Filling Machine for Food/Cosmetic/Beverage /Oil/Cream / Soap Liquid Paste Product Packing Machinery Machine Bottling Line

-

![Horizontal Sand Mill for Packaging Printing Ink]()

Horizontal Sand Mill for Packaging Printing Ink