Ribbon Type Mixer Big Model Bm-5000 Horizontal Low Speed for Plastic Powder Granules Mixing

Overview Product Description Double ribbon mixer, there are many different models, such as BM-500L,BM-1000L,BM-2000L,BM-

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | BM-5000 |

| Application Area | Engineering & Construction |

| Layout Type | Horizontal |

| Additional Capabilities | Coloring |

| Operating type | Continuous Operating |

| Condition | New |

| Suitable | Plastic Pellets,Powder |

| Function | Coloring and Mixing |

| Transport Package | Film Packed |

| Specification | 5000L |

| Trademark | BEIERMAN |

| Origin | China |

| HS Code | 847780000 |

| Production Capacity | 50 Per Quarter |

Product Description

Double ribbon mixer,

there are many different models, such as BM-500L,BM-1000L,BM-2000L,BM-3000L, BM-5000L

Pre-test by free before order

According to your needed , we can pre-test the material when it is meet your requirements.

Specification of ribbon mixer/blender

1. Mixing moderate and high uniformity, mixing uniformity CV≤5%, no segregation.

2. Mixed cycle short (180-240s), large open layout, a quick feed, a small amount of residue.

3. The feed mixer is widely used for mixing of powder, granular, flake, block, irregular and sticky materials in the industries of feed, cereal, food, chemicals, medicines, pesticides, etc.

4. The feed mixer is constituted by twin screw and atomizing system. The filling seal is adopted

for ends of shaft to improve tightness and prevent from leakage.

5. High mixing speed and homogeneity. Single shaft mixer makes materials can be mixed and no influenced for bulk density, filling degree in state of loss weight.

the Model BM-5000, 22KW , volume: 5000L, effective volume:3750LMachines photos:

Packaging & Shipping

Company Profile

Zhangjiagang Beierman Machinery CO.,LTD.is a modern factory, which engaged in the plastic extrusion machine and recycling machines' researching, manufacturing and saling. Our professional research teams, sales teams, rich experience and processing equipment will offer customers high quality machines and perfect after sales services.

Our major products including: single screw extruder, twin screw extruder, HDPE pipe production line, PP-R pipe production line, PVC pipe production line, plastic profile production line, plastic mixing machine, waste plastic recycling machines, plastic pelletizing machines and relative auxiliary machines for the plastic machines. We will offer the customers the whole set of solution from extrusion to recycling and turn key projects. Our machines are highly praised by our customers for perfect perfomance, quick service, advantage technology.

Customer's satisfied is our target forever. We will offer detail solutions according to different customers detail conditions. Customers' expected products, services is what we are always insisting. High quality, Quick services, mutually beneficial will our promise to customers around the world.

We Beierman Machinery can supply major machines as below 14items:

1,Mixing unit (Vertical , or Horizontal),high speed mixer~~~for PVC powder;

Ribbon mixer, low speed mixer~~~for PVC powder;

Hopper dryer mixer~~~for plastic granules;

Color mixer~~~for plastic granules.

2, PC LED light diffuser,bottom tube making line.

3, Supermarket Price tag profile production line; Soft seal production line; Rigid rod production line.

4,Single screw extruder;

5,Conical twin screw extruder;

6, 2layer; 3 layer;4 layer PPR pipe co-extrusion line; PPR, PE, HDPE, PE-RT pipe production line;

7, Corrugated pipe extrusion line (Single wall corrugated; Double wall corrugated);

8, 3 layer PVC pipe co-extrusion line; PVC pipe production line;

9, PVC 2 cavity pipe production line;

10, PVC 4 cavity pipe production line;

11,Pipe belling machine;

12, PVC rain gutter profile line; Trunking/panel profile line;WPC profile production line; and 2 layer PVC profile co-extrusion line;

13, Granulating line-water ring granulating,or string granulating (PP PE );

14, Granulating line-hot die face granulating (PVC).

After Sales Service

Pre-sales services

we will take customers to visit our factory and check the machines quality from airport/bus station/train stations

- we will re-designed the machines according to customer's different raw material formulations: driving motors power, electric power model, wall thickness of barrel, control method

After-sales services

we will offer electric diagram, installation diagram, usage manual

- we will offer the customers online introduction to solve the machines problems/send engineers for customers machines installation, running test, workers training, machines repairmen services.

- we will offer customers spare parts at cost prices all life long of the machines.

Exhibition

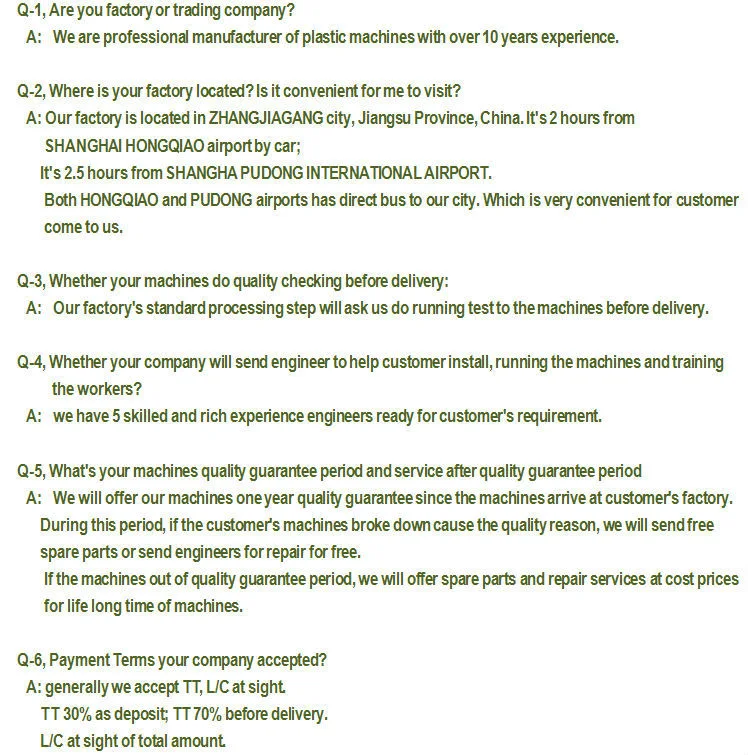

FAQ

Related Products

-

![Automatic Granule Powder Filling Machine Tea Rice Flour Coffee Bean Quantitative Weighing Packing Machine]()

Automatic Granule Powder Filling Machine Tea Rice Flour Coffee Bean Quantitative Weighing Packing Machine

-

![Automatic Milk Juice Drinking Water Sachet Liquid Filling Packing Machine with Bags]()

Automatic Milk Juice Drinking Water Sachet Liquid Filling Packing Machine with Bags

-

![Hot Filling/Warm Bottle Filler Bottled Water Carbonated Soft Juice Drink Bottling Filling Machine Bottle Washing Filling Capping Labeling Packing Machine]()

Hot Filling/Warm Bottle Filler Bottled Water Carbonated Soft Juice Drink Bottling Filling Machine Bottle Washing Filling Capping Labeling Packing Machine

-

![Automatic Can Customize Carton Filling Machine for Bottle Filling Carton Packing Machine]()

Automatic Can Customize Carton Filling Machine for Bottle Filling Carton Packing Machine