Wet Grinding Ball Mill Machine Prices Mining and Grinding Ore Equipment

All along, Zhongjia heavy industry has been following the trend and actively promoting the development of the industry.

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | MQG1200*4500 |

| Rotationl Speed | 21-23r/min |

| Application | Mine |

| Materials | Old Ore, Copper, Aluminum Powder, Perlite, |

| Condition | New |

| Warranty | 1year |

| After-sales Service | Installation Guide, Spare Part Supplying |

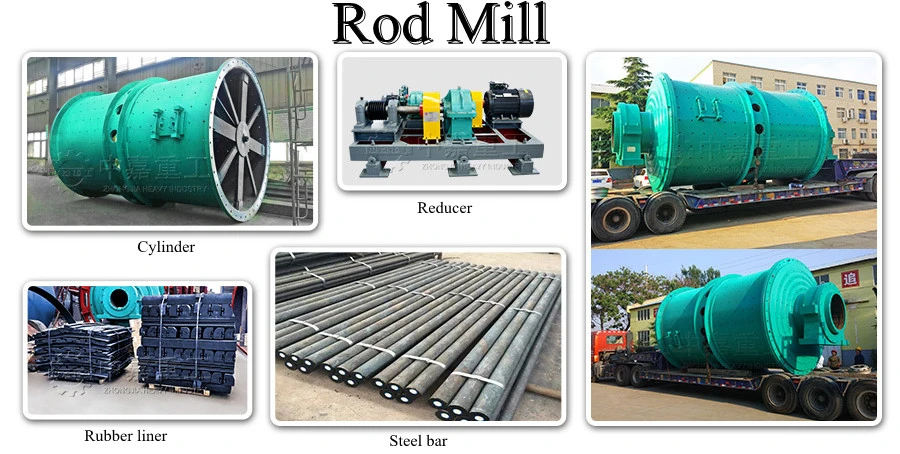

| Grinding Medium | Steel Rods,Balls, Ceramic Balls |

| Lining Plate Material | Rubber,Steel,Ceramic |

| Factory Visit | Welcome |

| Color | as Your Requirement |

| Product Name | Rod Mill |

| Certificate | CE.ISO |

| Machine Test | Provide |

| Transport Package | Container |

| Trademark | ZJZG |

| Origin | Zhengzhou |

| HS Code | 84742020 |

| Production Capacity | 1-140t/H |

Product Description

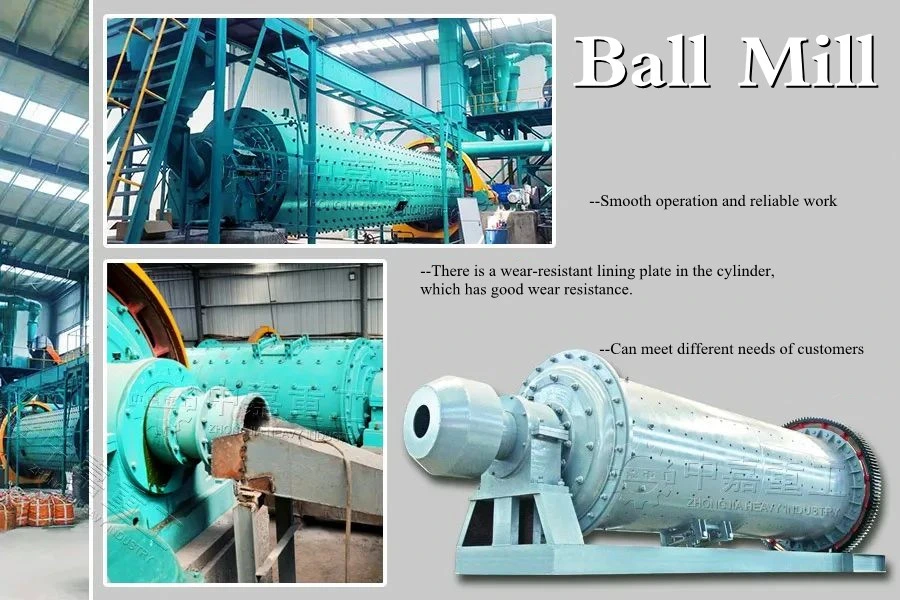

All along, Zhongjia heavy industry has been following the trend and actively promoting the development of the industry. Whether it is energy-saving ball mill, overflow ball mill, ceramic ball mill, water slag ball mill, tire ball mill and other ball mill products, it can always take the lead in the market.Nowadays, energy-saving ball mill has become a necessary choice in the field of ball mill, and has become one of the pillar properties in this field. In addition, the features of energy-saving ball mill, such as energy-saving, oil-saving, high-yield, etc., have become the recommended choice for the current coal, electricity industry, cement industry, building materials industry, chemical industry and other industries.

The ceramic ball mill is divided into two types: intermittent ceramic ball mill and continuous ceramic ball mill. The linings and grinding balls of the two ceramic ball mills are made of ceramic. The purpose is to make up for the inapplicability of the steel ball mill in some grinding operations, so as to ensure the purity, purity and chromaticity of the grinding materials and ensure the quality of the grinding products.

Our factory has many years of experience in ball mill production. The ball mills produced are not only of good quality and performance, but more importantly, they can greatly improve the economic benefits of the customer's concentrator. In the process of grinding, the number of equipment failures is very small, which reduces the customer's operating costs. The ball mill has been exported to more than 20 countries and has been widely praised by customers. This will be the source and motive force for our continued efforts to develop and innovate!

Welcome to contact us and communicate any questions about the machine. We are happy to help you!

Related Products

-

![PVC Mixer for Mixing Powderplastic Granule Powder Vertical Mixer Machine]()

PVC Mixer for Mixing Powderplastic Granule Powder Vertical Mixer Machine

-

![Complete in Specifications Double-Screw Powder Granule Conical Screw Mixer]()

Complete in Specifications Double-Screw Powder Granule Conical Screw Mixer

-

![PVC Additive PVC Compounding System Formula Automatic Weighing System / Automatic Dosing System]()

PVC Additive PVC Compounding System Formula Automatic Weighing System / Automatic Dosing System

-

![CE Certification High Productivity Commercial Dough Kneading Machine Vertical Dough Mixer Dough Kneader Spiral Dough Mixer]()

CE Certification High Productivity Commercial Dough Kneading Machine Vertical Dough Mixer Dough Kneader Spiral Dough Mixer